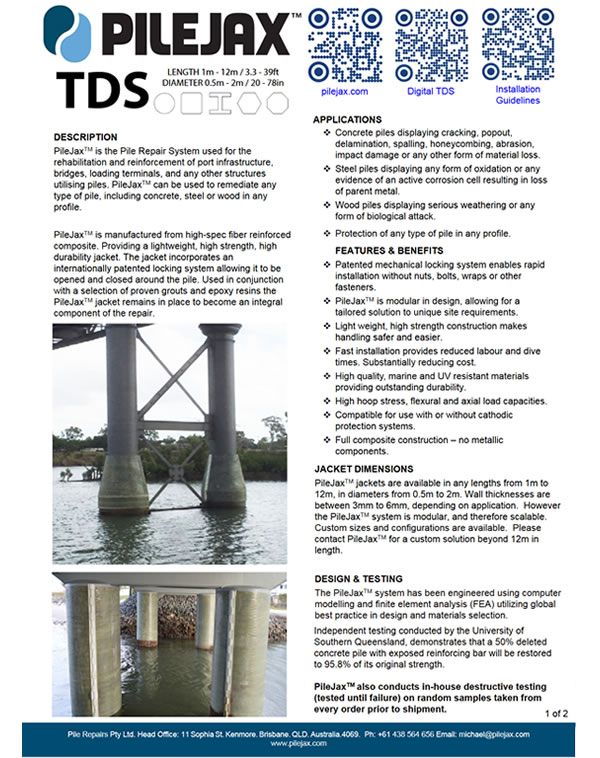

Technical Information

The PileJax™ Advantage

Strength – Independent testing by University of Southern Queensland confirms that a correctly executed PileJax™ repair will restore a 50% depleted concrete pile with exposed rebar to 95.8% of its original strength. The system can be used on any type of pile, concrete, steel or wood. In any profile.

Durability – Expected service life is over 45 years. Once the repair has been executed correctly it’s permanent. No need to rework or revisit the repair, no bolts to go missing over time, no wrap to come loose with wave action. Once the patented locking system is locked together and filled, the repair will last over 45 years.

PileJax™ The Real Advantage

The real advantage of the PileJax™ system is the reduction of billable hours. PileJax™ is so fast and easy to deploy it cuts down dramatically on billable hours across the project. Fast deployment, permanent results. PileJax™ Do it once and Do it right.

Download our TDS and Installation Guidelines

Additional Technical Capacity

Modular Design

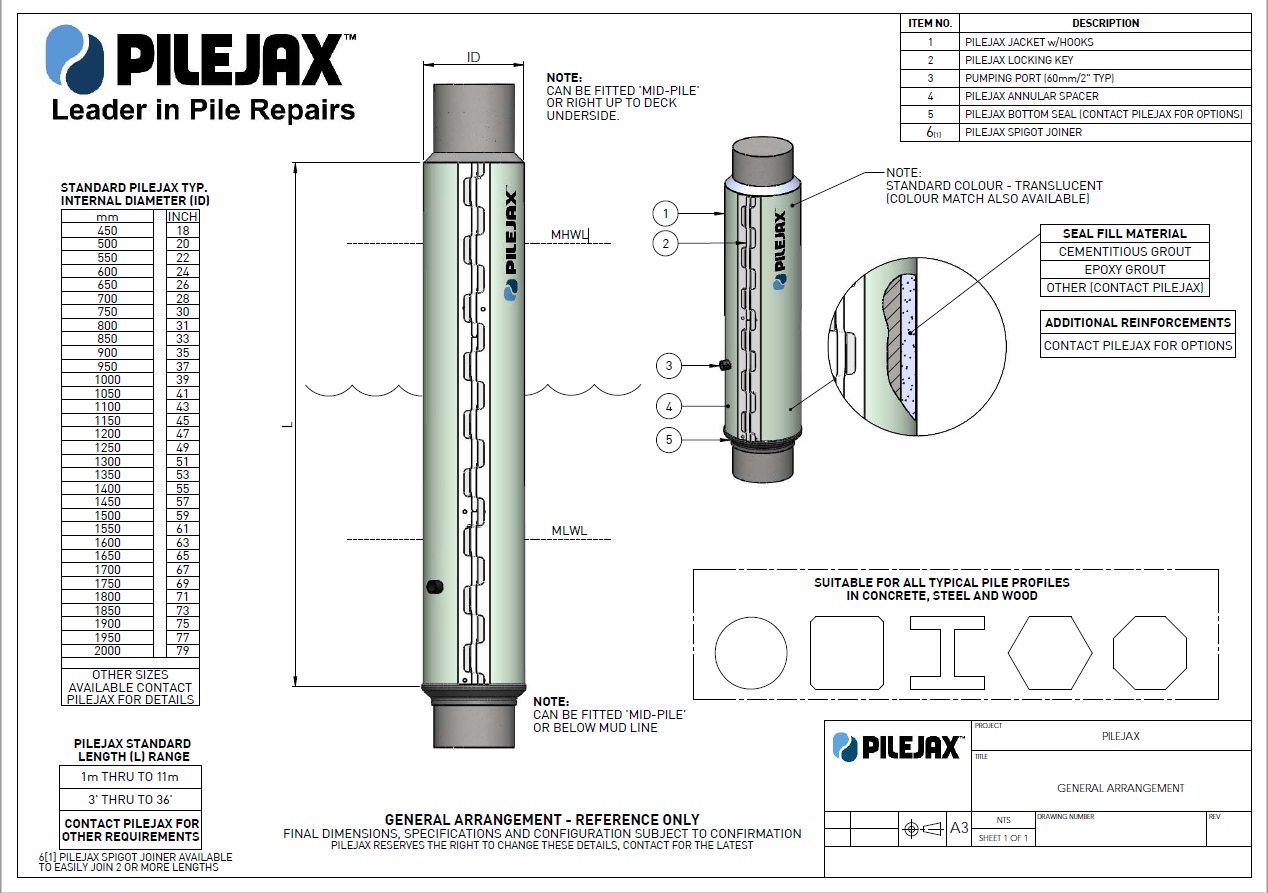

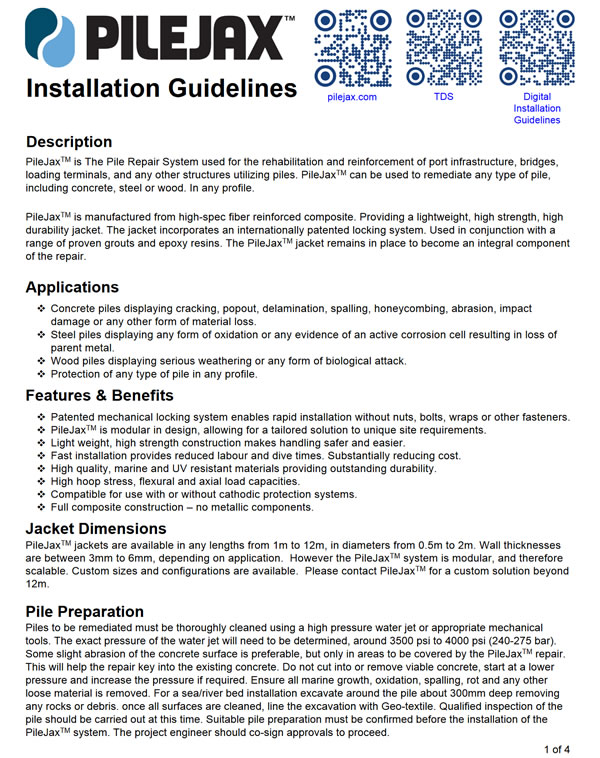

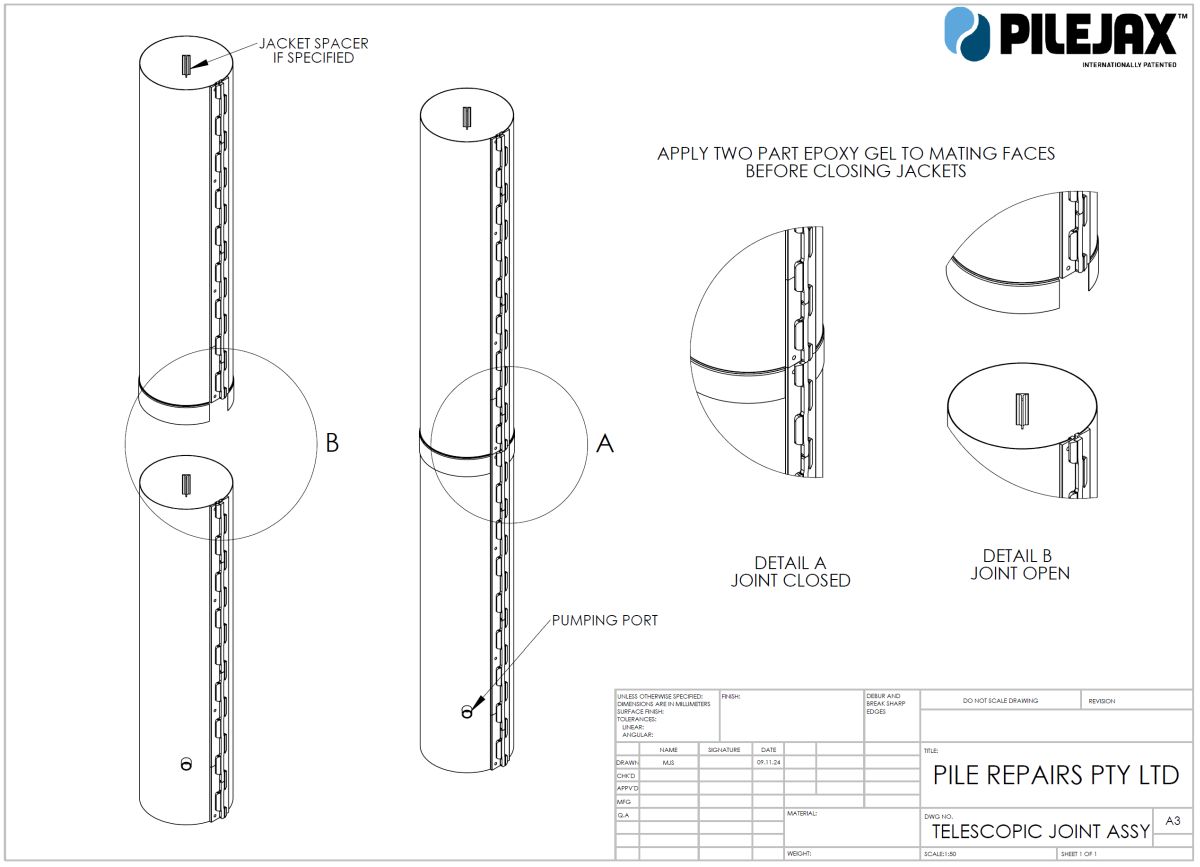

However the PileJax™ system is modular, and therefore scalable. The jackets can be made so that they telescope together. In the custom configuration the jackets become stackable, fitting end on end to produce the required length. Please contact PileJax™ for a custom solution beyond 12m.

Modular Design

However the PileJax™ system is modular, and therefore scalable. The jackets can be made so that they telescope together. In the custom configuration the jackets become stackable, fitting end on end to produce the required length. Please contact PileJax™ for a custom solution beyond 12m.

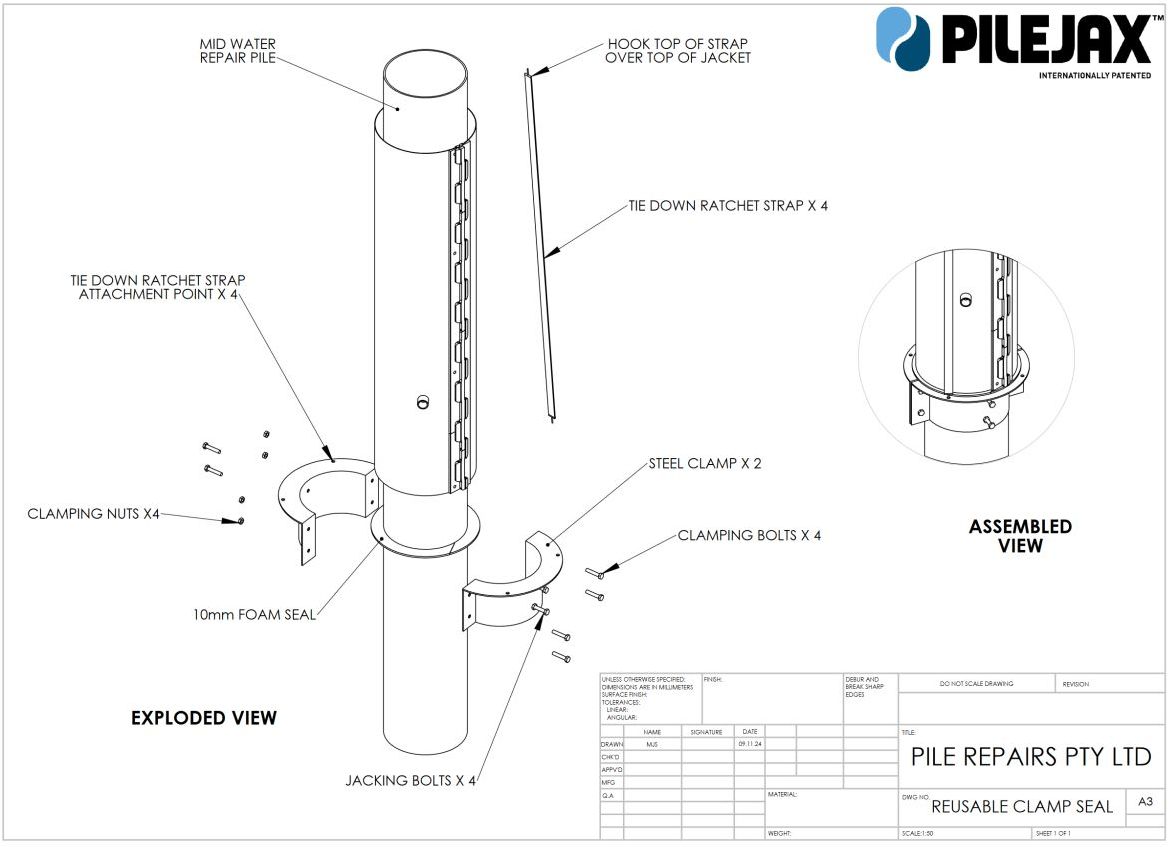

Midwater Only Repair

For large jobs, with multiple midwater only pile repair requirements, the reusable clamp and seal is recommended. The reusable seal is comprised of a metal clamp that bolts to the pile, and a flat foam seal. The jacket is made water tight by the interface with the seal and supported by the clamp. Straps are used to pull the jacket down onto the clamp forming the seal and stabilising the jacket. The clamp provides temporary support for the jacket during the filling operation. Once the repair has cured to a sufficient hardness, the clamps can be removed and used on the next repair location. For large jobs we recommend using several clamps in a leapfrog fashion.

Corrosion and Pile Degradation

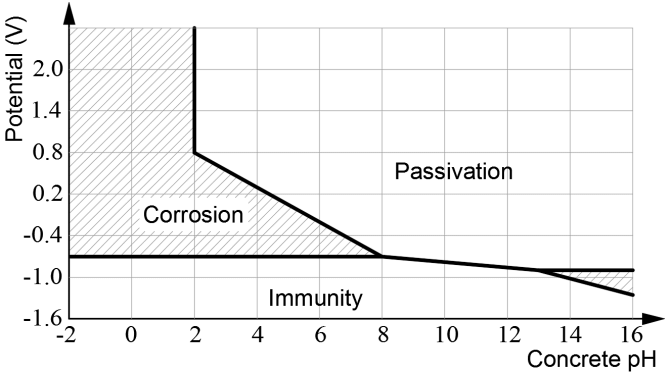

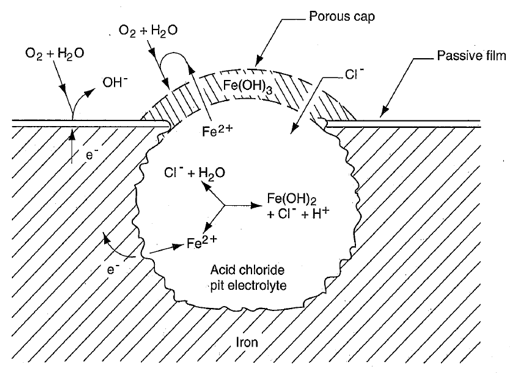

Passivation

This graph is the Pourbaix Diagram. The diagram illustrates the zones of immunity, corrosion and passivation for steel, and the corresponding PH and electrical potential for each. Concrete protects steel by way of passivation. The high PH of concrete prevents a corrosion cell from forming. The PH of concrete can be reduced over time by water ingress. As this happens the steel reinforcing cage inside the concrete moves from the passivation zone to the corrosion zone. When this happens the concrete pile will start to break apart from the inside because steel expands as it corrodes.

Passivation

Cathodic Protection

Divers can take CP readings with a Bathycorrometer to determine if a steel pile is protected, over protected, under protected or unprotected.

| Material | Expected CP reading |

|---|---|

| Over protected steel | More negative than -1100mV |

| Zinc (used for pre and post calibration) | -1000mV to -1050mV |

| Protected steel | -800mV to -1100mV |

| Under protected steel | -640mV to -800mV |

| Unprotected steel | -450mV to 640mV |

| Monel | -50mV to -150mV |

Over protection will not occur with sacrificial anodes, but may be achieved with an impressed current system.

No metallic components are used in the construction the PileJax™ pile repair system. The PileJax™ system is 100% composite, it is fully compatible with impressed current and sacrificial anode protection.